Types of Kitchen Cabinet Handle Screws

Choosing the right screws for your kitchen cabinet handles is crucial for ensuring a secure and long-lasting installation. Understanding the different types of screws available and their suitability for specific applications is essential for achieving a professional-looking finish. This guide explores the common types of screws used for kitchen cabinet handles, highlighting their advantages and disadvantages, and providing examples of where they are best suited.

Wood Screws

Wood screws are the most common type of screw used for kitchen cabinet handles. They are available in a variety of sizes and finishes to match the hardware. Wood screws are designed to be driven into wood, creating a strong and secure connection.

The advantages of using wood screws include:

- Strong and secure hold in wood.

- Available in various sizes and finishes to match the hardware.

- Relatively inexpensive.

The disadvantages of using wood screws include:

- Can be difficult to remove without damaging the wood.

- May not be suitable for all types of wood, such as softwoods or plywood.

Wood screws are typically used for installing handles on solid wood cabinets, where the screw can be driven directly into the wood.

Self-Tapping Screws

Self-tapping screws are designed to cut their own threads into the material they are being driven into. This makes them ideal for use in materials like metal, plastic, or even drywall.

The advantages of using self-tapping screws include:

- Easy to install, as they do not require pre-drilling.

- Suitable for a variety of materials.

- Available in different lengths and thread types.

The disadvantages of using self-tapping screws include:

- May not provide as strong a hold as wood screws in wood.

- Can be more difficult to remove than wood screws.

Self-tapping screws are often used for installing handles on metal cabinets or when the cabinet material is too thin for wood screws.

Drywall Screws

Drywall screws are designed specifically for use in drywall. They have a fine thread and a sharp point, making them easy to drive into drywall without splitting the material.

The advantages of using drywall screws include:

- Easy to drive into drywall without splitting the material.

- Available in different lengths to accommodate varying thicknesses of drywall.

- Relatively inexpensive.

The disadvantages of using drywall screws include:

- May not be strong enough for use in other materials, such as wood or metal.

- Can be difficult to remove without damaging the drywall.

Drywall screws are commonly used for installing handles on cabinets made of drywall or when the cabinet is mounted to a drywall wall.

Cabinet Screws

Cabinet screws are a specialized type of screw designed specifically for use in kitchen cabinets. They are typically made of a durable metal and have a unique thread pattern that provides a strong hold in wood.

The advantages of using cabinet screws include:

- Designed for use in kitchen cabinets, providing a strong and secure hold.

- Available in a variety of sizes and finishes.

- Typically have a self-tapping point, making installation easier.

The disadvantages of using cabinet screws include:

- May be more expensive than other types of screws.

- Not suitable for use in other materials.

Cabinet screws are the best choice for installing handles on kitchen cabinets, as they are specifically designed for this purpose and provide the strongest hold.

Choosing the Right Screws

The best type of screw to use for your kitchen cabinet handles will depend on the material of the cabinet, the thickness of the material, and the type of handle being installed. Consider the following factors when making your selection:

- Material: If the cabinet is made of wood, wood screws are the best choice. If the cabinet is made of metal or drywall, self-tapping screws or drywall screws may be more suitable.

- Thickness: If the cabinet material is thin, self-tapping screws or drywall screws may be a better option than wood screws. If the material is thick, wood screws or cabinet screws will provide a stronger hold.

- Handle Type: The type of handle being installed will also affect the choice of screw. Some handles have pre-drilled holes that require specific screw sizes.

Choosing the Right Screw Size and Length

Selecting the appropriate screw size and length for your kitchen cabinet handles is crucial for ensuring a secure and aesthetically pleasing installation. Using the wrong screws can lead to loose handles, damage to your cabinets, or even a wobbly installation.

Screw Length and Cabinet Material

The length of the screw you need will depend on the thickness of your cabinet doors and the type of handle you’ve chosen. Here’s a general guideline:

For standard cabinet doors (typically 3/4″ thick), screws between 1″ and 1-1/4″ in length are usually sufficient.

For thicker cabinet doors, longer screws may be required.

For thinner doors, shorter screws might be needed.

Screw Size and Handle Type

The diameter of the screw, also known as the screw size, is important for a secure hold and compatibility with the handle’s mounting holes.

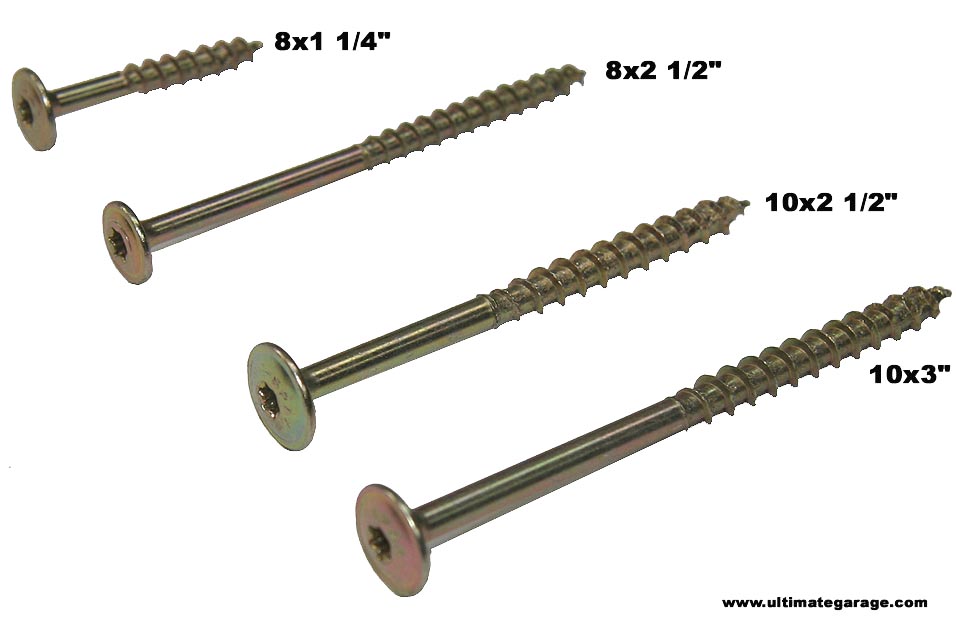

For most standard kitchen cabinet handles, screws with a diameter of #8 or #10 are commonly used.

For larger or heavier handles, you might need larger screws, such as #12.

Common Screw Sizes and Applications

Here’s a table with examples of common screw sizes and their corresponding applications:

| Screw Size | Application |

|---|---|

| #6 | Lightweight handles, thin cabinet doors |

| #8 | Standard handles, most cabinet doors |

| #10 | Heavier handles, thicker cabinet doors |

| #12 | Very heavy handles, thick cabinet doors |

Installation Techniques and Tips: Kitchen Cabinet Handle Screws

Installing kitchen cabinet handle screws is a straightforward process, but a few tips and tricks can make the job easier and ensure a professional finish.

Steps Involved in Installing Kitchen Cabinet Handle Screws

This section will explain the steps involved in installing kitchen cabinet handle screws.

- Mark the Screw Locations: Use a pencil to mark the screw locations on the cabinet door or drawer front. This is essential for precise placement and symmetry.

- Pre-Drill Pilot Holes: Before driving in the screws, pre-drill pilot holes slightly smaller than the screw diameter. This will prevent the wood from splitting and make installation easier.

- Install the Screws: Using a screwdriver or drill, carefully drive the screws into the pre-drilled pilot holes. Ensure the screws are fully seated and that the handle is securely attached.

- Tighten the Screws: Once the screws are installed, tighten them using a screwdriver or drill with a Phillips head bit. Tighten them just enough to secure the handle without overtightening, which could damage the wood or the handle.

Tips and Tricks for Secure and Aesthetically Pleasing Installation, Kitchen cabinet handle screws

This section will provide tips and tricks for ensuring a secure and aesthetically pleasing installation.

- Use a Level: Ensure the handle is level before securing it with screws. A level will help ensure the handle is installed straight and symmetrical.

- Consider the Screw Length: Use screws that are long enough to reach through the handle and into the cabinet door or drawer front. However, avoid using screws that are too long, as they could protrude through the back of the door or drawer front.

- Use a Magnetic Screwdriver: A magnetic screwdriver will make it easier to hold the screw in place while driving it in. This is especially helpful for reaching into tight spaces.

- Pre-Finish the Screws: If you are using exposed screws, consider pre-finishing them to match the cabinet hardware. This will give the installation a more polished look.

Tools and Materials Needed for Installation

This section will discuss the tools and materials needed for installing kitchen cabinet handle screws.

- Screwdriver or Drill: A screwdriver or drill with a Phillips head bit is essential for driving in the screws.

- Pencil: A pencil is needed to mark the screw locations on the cabinet door or drawer front.

- Level: A level will help ensure the handle is installed straight and symmetrical.

- Pilot Drill: A pilot drill is needed to pre-drill pilot holes before driving in the screws.

- Screws: Choose screws that are the appropriate size and length for your cabinet hardware and wood thickness.

Ngomongin soal kitchen cabinet handle screws, inget deh sama Ikea. Kalo lagi nyari lemari buat kamar mandi, coba deh cek ikea tallboy bathroom cabinet. Keren banget desainnya, bisa dipaduin sama handle-handle yang unik. Terus, pastiin kamu punya cukup kitchen cabinet handle screws ya, biar handle-nya awet dan gak gampang copot.

Nah, siapa sih yang gak pusing sama urusan sekrup pegangan kabinet dapur? Pasti sering banget ngalamin sekrupnya longgar, bikin pegangannya goyang-goyang. Eh, tapi ngomong-ngomong soal kabinet, kalian tau gak sih kalau kabinet kayu di kamar mandi itu keren banget?

Coba deh cek link ini buat liat inspirasi desainnya. Nah, balik lagi ke sekrup pegangan kabinet dapur, kalau sekrupnya udah aus, ganti aja langsung! Biar kabinetnya tetep awet dan cakep.